Food Distribution Network Impact

November 7, 2023It seems appropriate to send the American Truck Wash winter newsletter on the first full day of winter. Yes, at 8:27 PM Mountain Standard Time on December 21st, the earth reached its maximum tilt from the sun signifying the official beginning of winter in the northern hemisphere and summer in the southern.

That also means that Christmas is only a few days away. Most likely, by the time you see this, you will be returning from your time with family over the Holidays. And we trust you had a wonderful time.

Water Reclaim Systems

To start the New Year out, we thought we’d take a few paragraphs here to go over the basics of water reclamation systems, some of their limitations and benefits.

You may not know, but most municipalities are mandating water reclamation systems before business licenses or building permits will be approved these days for a car or truck wash. When it comes to washing trucks, a reclaim system can also be a money saver as you can imagine that it takes a lot more water to wash a 75-foot big rig than it does your Ford Escape.

As you may have guessed, reclaim water is water that has been used in the wash bay and is then treated in some manner to remove the solids and then returned to the wash system. Some systems may apply other treatment steps to improve the water quality, but please be aware; reclaim water is not clean water! It is simply dirty water with most of the dirt and oil removed and something done to kill bacteria and prevent algae from growing in the system. Reclaim water can be reused in some of the portions of a truck wash system, but it is not recommended to use reclaim water in the chemical applications or obviously, the final rinse step. Therefore, on a typical truck wash system, you will only be able to recover about 60-65% of the water used (depending on options) in the process.

Additionally, water reclaim systems do not remove salt or other dissolved ions from the water. The good news is that since the system doesn’t recycle 100% of the water, the new water added to the wash process from the chemical application and rinse cycles will dilute ions and prevent them from reaching the saturation point (where they will come out of solution and start plugging everything up).

Systems:

There are several different systems/technologies employed to clean up the water enough to be reused:

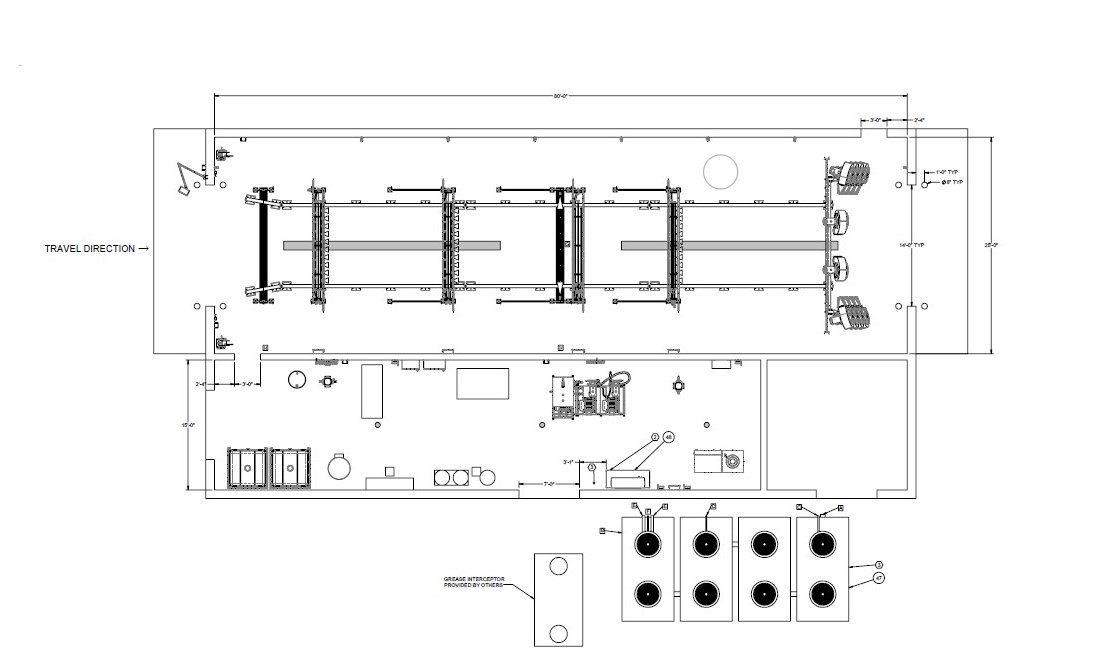

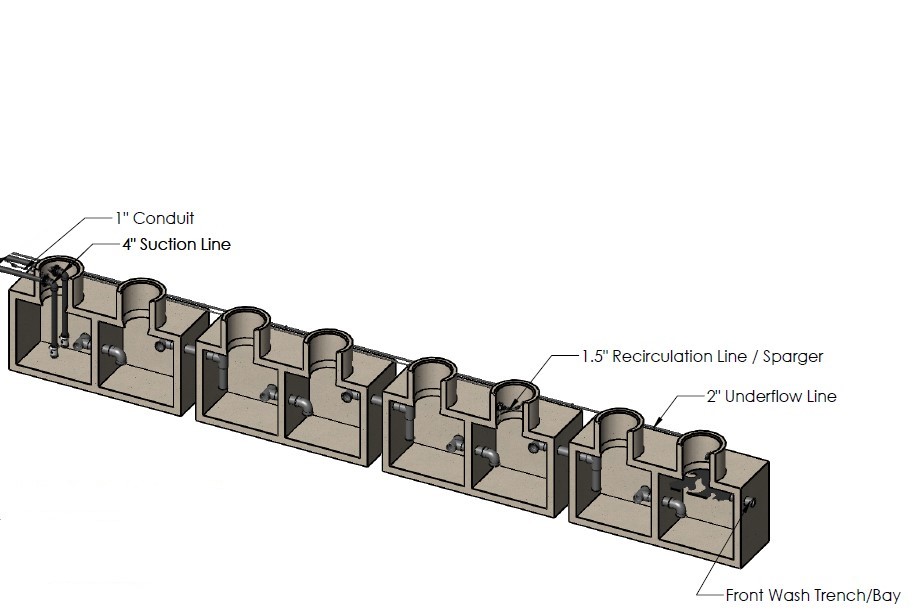

- Tank System – this system is simply a series of below or above ground settling chambers for the water to move slowly through so that the solids will settle. Tank systems need to be sized correctly and are available with different options to improve water clarity. Tank system performance can also be enhanced with the addition of polymers to improve settling and clarity.

- Cyclone Systems - These systems employ more sophisticated controls and machinery and most often are placed after a series of settling tanks. They are not designed to handle large solids or high volumes of solids so some settling tanks are a prerequisite.

- Filter Systems – these use a series of enclosed tanks with some sort of media in them to trap solids and remove organics. They are not common in wash systems as they tend to be expensive and high maintenance. Some systems are very simple though and can consist of a series of self-flushing cannister strainers.

- Bacteria/Algae Control - All reclaim systems run the risk of living organisms taking hold and growing. Some of these microbes can be dangerous (like giardia & cryptosporidium), but most are just annoying and make your wash bay smell bad. There are several different technologies for controlling microorganism growth such as:

- Chemicals; Bleach, bromines, etc.

- Ozone

- Air sparging

- Ultraviolet light

- Or combinations of the above

Economics:

As an example, we are using an American Truck Wash Freedom Gantry System to demonstrate how much water can be reused with a proper reclamation system. This is because it is the system we know! (Not to mention it is the best.)

Based on our system flowrates, pressures, and number of nozzles, a full-deluxe wash on a 75’ semi and trailer with 2 chemical applications, a high-pressure wash and rinse will take about 280 gallons of water. That’s enough to take 4 baths in your typical tub. Add in another 50-60 gallons for an undercarriage blast and you will use 340 gallons. Of that, about 100 gallons is used in the chemical and rinse cycles. That leaves about 240 gallons that can be reused in theory. However, some water is lost when the truck drives out and some to evaporation. Therefore, about 220 gallons of water can be reclaimed on average.

If you wash 30 trucks per day, that calculates to 6600 gallons a day. I recently found the commercial cost for water in one city to be right at $4 per 1000 gallons. At that rate, the reclaim system will reduce your cost by $26.40 per day. And that does not include the corresponding sewer cost.

There is a lot more to water reclaim systems.

Obviously, we can’t finish a winter newsletter without an image of winter in Montana. And we think it appropriate to share an image from YNP.